PRODUCTS

DVI Cable

DVI-2Y(St)CH-4P/1P/3C-24

- (7P+1P+3C)

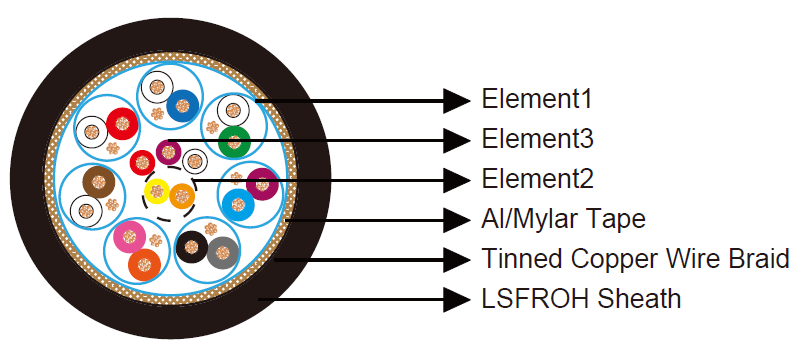

Construction

Element 1: 7PR×24AWG(CU/ PE/Individual Al-mylar Screen+ TC Drain Wire)

-

Conductors Stranded tinned copper wires, 7/0.20mm Insulation Foam Polyethylene. Core Identification 1P= White/Brown; 2P=White/Red; 3P=White/Green; 4P=White/Blue; 5P=Grey/Black; 6P=Pink/Orange; 7P=Light Blue/Purple Twisting The cores shall twisted together in pair, the lay between each twist shall not exceed 100 mm Individual Shield Aluminum/mylar laminated tape applied with the metallic side down in electrical contact with a 24AWG tinned copper drain wire (7 strands formation).

A 23 mylar tape is applied over the screening tape with a minimum 25% overlap.

-

Conductors Stranded annealed tinned copper wire, 7/0.20mm Insulation Foam polyethylene. Thickness 0.15mm. Outer diameter 0.9mm Insulation Color Yellow/Orange Twisting The cores shall twisted together in pair, the lay between each twist shall not exceed 100 mm -

Conductors Stranded annealed tinned copper wire, 7/0.20mm Insulation Foam polyethylene. Thickness 0.15mm. Outer diameter 0.9mm Insulation Color Red/Purple/White -

Overall Screen Aluminum/mylar tape. Braid Shield Braid of tinned copper wire (0.12mm). Coverage: 25%

Outer Sheath LSOH sheath,Thickness 1.2mm. Outer diameter is 12.5mm

Other material is optional.

Sheath Color Black or as per client's requirement. -

Rated Voltage 30V Max conductor resistance at 20°C ≤94.2 Ohm/Km Min insulation resistance ≥100M Ohm/m Spark test Min. AC 250V/1 second Nom. mutual capacitance at 1KHz 57 pF/m -

EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2) Vertical flame propogation for a single insulated wire or cable EN 50266-2-4 + EN 50305; IEC 60332-3-24;

NF C 32-070 2.2 (C1); VDE 0472 Teil 804Vertical flame spread of vertically mounted bunched wires or cables EN 50268-2; IEC 61034-2; NF C 32-073 ;

NF C 20-902; NF F 16 101; VDE 0472 Teil 816Low Smoke Emission EN 50267-2-1; IEC 60754-1; NF C 32-074;

NF C 20-454; VDE 0472 Teil 815Halogen Free EN 50267-2-2/3; IEC 60754-2; NF C 32-074;

NF C 20-453; VDE 0472 Teil 813

Low Corrosivity (Acidity & Conductivity) EN 50305; NF X 70-100; NF F 63 808; TM1-04; BS6853 Low Toxicity NF F 63 808; BS6853; NF F 16 101 Smoke index EN45545-2 Requirement for fire behavior of materials & components R15/R16

Element 2: 1PR×24AWG(7/0.2mm) Stranded TC/Foam PE

Element 3: 3C×24AWG(7/0.2mm) Stranded TC/Foam PE

Element Assembly

Physical Properties:

Temperature rating: -25°C to +80°C

Minimum bending radius:

Fixed installation: 5 x Overall Diameter

Sporadic movement: 10 x Overall Diameter

Electrical Properties:

Fire Performance in General :

Fire Performance Relating to Rolling Stock Application

DIN 5510-2

BS 6853

NF F16 101

NF F 63 808

EN 45545-2

|

|

|

|

|

|

Corona Resistant |

Highly Flexible |

UV Resistant |

Ozone Resistant | Abrasion Retardant |

Cold- resistant |

|

|

|

|

|

|

Resistance To Soldering Heat |

Acid&Alkaline Resistant |

IRM 903 Fuel Oil Resistant |

IRM 902 Mineral Oil Resistant |

Fire Retardant NF C32-070-2.2(C2) IEC60332-3-24/EN50266-2-4 |

Flame Retardant NF C32-070-2.1(C1) IEC60332-1-2/EN50265-2-1 |

|

|

|

|

Low Toxicity NF X70-100/NF F63 808 TM1-04/BS 6853 |

Low Corrosivity IEC60754-2/EN50267-2-2/3 NF C32-074/VDE 0472-813 |

Low Smoke Emission IEC 61034-2 / EN 50268-2 NF C32-073/VDE 0472-816 |

Zero Halogen IEC 60754-1/EN 50267-2-1 NF C32-074//VDE 0472-815 |